εγκαταστασεις-λαππα-slider

WATER WELL PIPES

PUMPING SYSTEMS

ΣΩΛΗΝΕΣ ΓΕΩΤΡΗΣΕΩΝ

since 1983

ΑΝΤΛΗΤΙΚΑ ΣΥΣΤΗΜΑΤΑ

The company V. Liarommatis SA produces water well pipes. Their production is done from automatic production lines using CNC machine tools and special robot machines. Also, high quality raw materials are used. All this together with the certification of our company with the Quality Certificate EN ISO 9001: 2015 guarantee to our customers that our products are of high quality, based on the strictest specifications and at a very competitive price compared to their quality. Water well pipes have two main categories about the material from which they are made:

The V. Liarommatis Company produces longitudinally welded base pipes type ER/HFW (Electric Resistance/High Frequency Welding) as per DIN 1626/2-2458 with a diameter of 5″ – 12″3/4 and length 6m without circumferential welding seams using high quality raw materials. The sheet steel used for pipe manufacture is St37 or St42 steel, 3-7mm thick and/or AISI 304 or AISI 316 stainless steel, 3-6mm thick. The metal bridge type slotted screens, manufactured, as per DIN 4922 are made for longitudinal welded (ERW) base pipes ER/HFW (Electric Resistance / High Frequency Welding) as per DIN 1626/2-2458 with a diameter of 5″ – 12″3/4 and a length of 6m without circumferential welding seams.

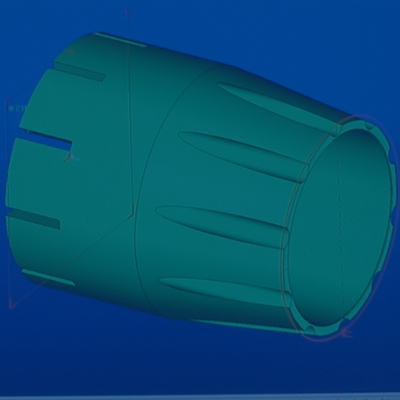

The V. Liarommatis Company also produces plastic PVC-U water well pipes and screens. Their production is done from an automatic production line with CNC machine tools using high quality raw materials. It is the largest plant in Greece, producing geo-drilling pipes as per DIN 4925.The broaching of screw threads on plastic pipes and screens is effected by a special CNC threading machine tool. The thread type is trapezoid as per DIN 4925, of 6mm – 12mm pitch according to pipe diameter. This type of thread is the most appropriate for water wells since it displays considerable load bearing capacity.

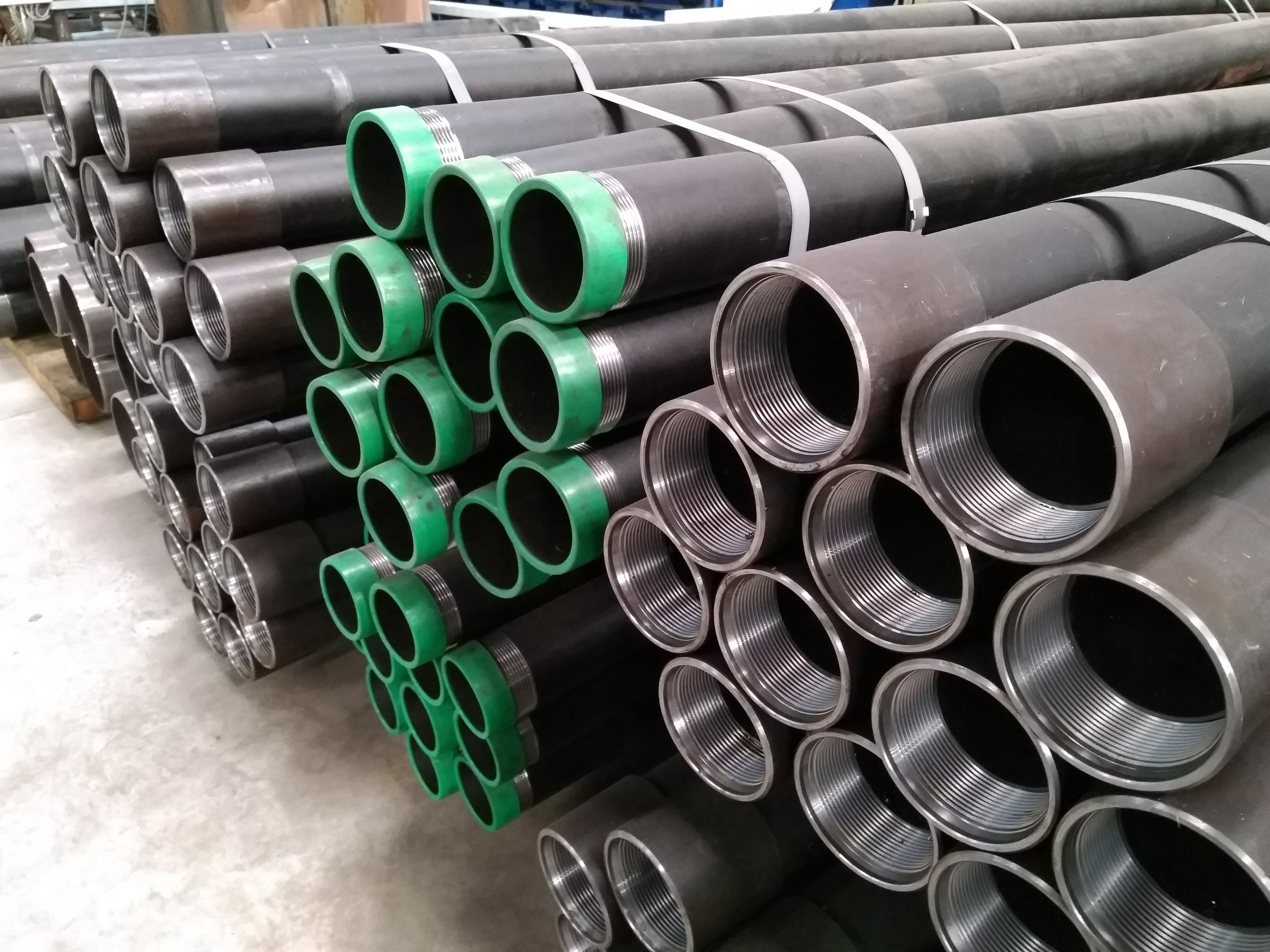

Steel and Stainless Steel Water Well Pipes and Screens |

The V. Liarommatis Company produces longitudinally welded base pipes type ER/HFW (Electric Resistance/High Frequency Welding) as per DIN 1626/2-2458 with a diameter of 5″ – 12″3/4 and length 6m without circumferential welding seams using high quality raw materials. |

Plastic PVC-U Water Well Pipes and Screens |

The V. Liarommatis Company also produces plastic PVC-U water well pipes and screens. Their production is done from an automatic production line with CNC machine tools using high quality raw materials. It is the largest plant in Greece, producing geo-drilling pipes as per DIN 4925. |

Pumping Systems |

The V. Liarommatis Company distributes the Italian submersible pumps PANELLI, PANELLI submersible electric motors for pumps and the entire range of products of PANELLI company. |

Pipes for Submersile Pumps |

Our company manufactures on CNC lathe threaded steel pipes according to the ASTM A53 standard of GRADE B quality steel and their socket connections at 2″- 8″ diameter and 3-6m in lengths. Also, galvanized and stainless steel pipes can be made on request. |

Polyethylene water well pipes |

In addition to the aforementioned, our company also manufactures polyethylene pipes and screens (High Density Polyethylene Pipes- PEAD) with threaded connections. These pipes are utilized in waste collection and transportation as well as fermentation gas transportation. |

Workshop attachments |

The company V. Liarommatis SA, because of modern CNC machine tools at its disposal, can produce high quality various components. For the design of products and support of CNC machine tools the company use a CAD-CAM software. |

The manufacture of high quality products, to the strictest specifications

Consistent product delivery within the shortest possible time

The optimum quality - cost ratio for our products

Water well pipes are metal or plastic pipes used to create the boreholes. These pipes allow the drilled material (such as oil, water or natural gas) to be brought to the surface.

Water well pipes can be made of various materials, such as steel, plastic, stainless steel, polyethylene (PE) or polyvinyl chloride (PVC), depending on the needs of the application.

Water well pipes are used to support the drilled opening and prevent it from collapsing. In addition, they can be used to transport material mined from the borehole to the surface.

There are several types of water well pipes, including:

When choosing water well pipes, we must take into account the following characteristics: